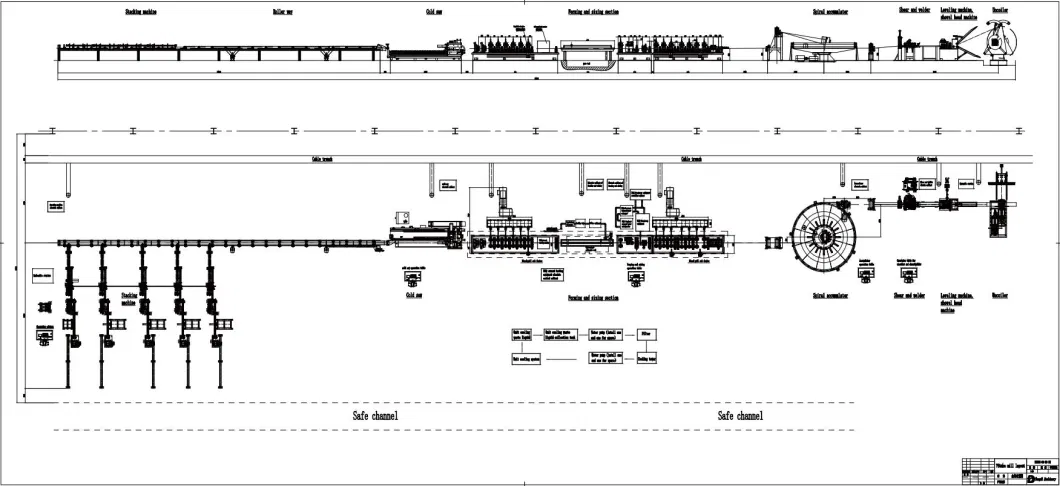

Stainless Steel/Building Materials Steel Pipe Making Machine/Carbon Steel Straight Seam Welded Pipe Making Machine/ Automatic Gi Pipe Ms Tube Mill Machine

Basic Info.

| Model NO. | Hg273 |

| Application | Industry |

| Type | High Frequency Weld Pipe Mill Line |

| Maximum Dhickness | 3.0-10.0mm |

| Lead Time | Est. Time(Days) 90 |

| Max Pipe Diameter | 89-273mm |

| Transport Package | Container Packing |

| Trademark | TENGDI |

| Origin | China |

| HS Code | 845510 |

Product Description

Are you looking for high-quality steel pipe making machine that will provide exceptional performance?

Tengdi Machinery is an excellent steel pipe making machine manufacturer with whom to explore collaborating. Tengdi provide a large selection of various steel pipe making machine choices that are intended to meet your unique requirements. We can be sure that you will get the finest steel pipe making line option for your needs. Tengdi collaborate with skilled specialists who contribute their years of experience and guarantee that all of our works meet the highest standards.

Quick Details| Manufacture | Tengdi Machinery | Name | ERW pipe making machine |

| Type | HF Solid state steel pipe welding production line | Line speed | ≤50m/min |

| Round pipe dia | 114-273mm | Round pipe thickness | 3.0-14.0mm |

| Square & rectangular pipe size | 90*90-200*200mm | Square & rectangular pipe thickness | 3.0-14.0mm |

| Pipe material | Carbon steel/Galvanized steel | Place of Origin | Shijiazhuang, China |

| Voltage | 220/380/415/440V | Forming method | FF |

| Model | Procession (mm) | Round thickness (mm) | Square/Rectanglar (mm) | Pipe thickness (mm) | Welding speed (m/min) |

| Φ50 | Φ19-Φ50 | 0.6-3.5 | 15*15-40*40 | 0.6-3.0 | 20-120 |

| Φ60 | Φ21-Φ60 | 0.8-3.5 | 15*15-50*50 | 0.8-3.0 | 20-120 |

| Φ76 | Φ21-Φ76 | 0.8-4.0 | 15*15-60*60 | 0.8-3.5 | 20-110 |

| Φ89 | Φ32-Φ89 | 1.0-4.5 | 25*25-70*70 | 1.0-4.0 | 20-100 |

| Φ114 | Φ48-Φ114 | 1.5-5.0 | 35*35-90*90 | 1.5-4.5 | 20-70 |

| Φ165 | Φ89-Φ165 | ≤8 | 70*70-130*130 | ≤7 | ≤60 |

| Φ219 | Φ102-Φ219 | ≤10 | 80*80-170*170 | ≤9 | ≤50 |

| Φ273 | Φ114-Φ273 | ≤14 | 90*90-200*200 | ≤12 | ≤40 |

| Φ325 | Φ127-Φ325 | ≤16 | 100*100-250*250 | ≤14 | ≤35 |

| Φ406 | Φ219-Φ406 | ≤16 | 170*170-300*300 | ≤14 | ≤30 |

| Φ660 | Φ325-Φ660 | ≤22 | 250*250-500*500 | ≤20 | ≤30 |

Q: Are you manufacturer?

A: Yes. We are manufacturer. We have our own technical team. Welcome to visit us.

Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details!

Q: What info you need before you make the proposal?

A: The pipe diameter and thickness range which you need or the profile drawings material information, your special requirements and speed of the machine.

Q: How do you do QA?

A: We have special team do strict QA, this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure it is in the range of tolerance critical parts will be inspected for all dimensions.

Q: Why choose you? What is the difference between you and other Chinese supplier?

A: You can get higher quality product & better professional service from TENGDI with same price.

Q: What I should do if just start a new business?

A: Contact us immediately, we provide free consultant pre-sales service