Steel Spiral Welded Pipe Line Machine Mill on Pipe Making Machine

Basic Info.

| Model NO. | SXHNGK |

| Delilvery Time | 10 Months |

| Transport Package | Wood Pallet |

| Specification | Metal |

| Trademark | SXHNGK |

| Origin | China |

| HS Code | 8501109101 |

| Production Capacity | 5 Sets |

Product Description

Front-swing spiral welded mill introduction:

The steel coils are unfolded and leveled by the mill equipment. And they are sent to the forming machine in a certain angle. Supplemented by a certain angle, the continual pipes are formed in the principle of three-roll rolling machine. Continual spiral welding is welded by submerged-arc welding machine. When the uncoiling, coil detaching, leveling, steel cutting and welding are working, the host machine needs to stop and wait. After the steel welding finishing, the host machine starts to work again. The front-swing spiral welded pipe mill adopts intermittent production method with advantages such as low investment, and simple convenient.

According to the different function of our products, the front swing spiral welded pipe mills are divides in to API standard model and national standard model. API standard model mainly produces the delivery pipe with petroleum or natural gas (long distance).the material and quality of the steel pipe need to be very good. The requirements for mill equipment and testing equipment also are very high. National standard model produces the pipe used for short distance delivery of natural gas or water, the pipeline construction in the city, the structure pipe, column pipe and so on. The requirements for the material and quality of the steel also are very high, second only to that of API standard.

Front swing spiral welded pipe mill model:

| No | Model | Specification | coil width (mm) | Thickness (mm) | Capacity (kw) | Area(M2) |

| 1 | HN-426 | Φ219~Φ426 | 300~600 | 3~14 | 200 | 24×200 |

| 2 | HN -529 | Φ219~Φ529 | 300~800 | 3~16 | 300 | 24×200 |

| 3 | HN -630 | Φ219~Φ630 | 300~1000 | 3~18 | 400 | 24×200 |

| 4 | HN -720 | Φ219~Φ720 | 300~1200 | 4~25.4 | 500 | 24×200 |

| 5 | HN-820 | Φ219~Φ820 | 350~1300 | 3~14 | 500 | 24×200 |

| 6 | HN -1020 | Φ273~Φ1020 | 350~1300 | 3~16 | 800 | 24×200 |

| 7 | HN -1420 | Φ325~Φ1420 | 500~1600 | 3~18 | 1000 | 24×200 |

| 8 | HN -1620 | Φ426~Φ1620 | 500~1600 | 4~25.4 | 1500 | 30×300 |

| 9 | HN -1820 | Φ508~Φ1820 | 500~2000 | 4~25.4 | 1500 | 30×300 |

| 10 | HN -2020 | Φ508~Φ2020 | 500~2000 | 4~25.4 | 1500 | 30×300 |

| 11 | HN -2400 | Φ508~Φ2400 | 500~2000 | 4~25.4 | 1800 | 30×300 |

| 12 | HN -3000 | Φ610~Φ3000 | 500~2000 | 4~25.4 | 1800 | 30×300 |

| 13 | HN -3500 | Φ720~Φ3500 | 600~2000 | 4~25.4 | 2000 | 30×300 |

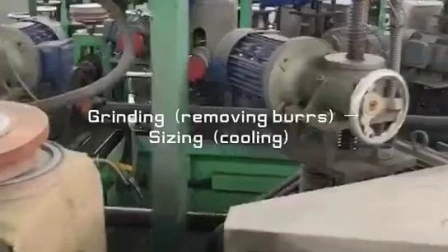

Front-swing spiral welded pipe mill production process:

Loading coil-uncoiling-leveling-cutting and coil welding -edge milling machine-feeding machine- prebending and guide board - forming machine-internal welding-external welding - tracking and cutting off -Pipe pulling out- welding seam grinding - pipe end expander -X-ray inspection -hydraulic testing - pipe end facing and beveling -ultrasonic inspection-pipe end take photo -weighting, measuring , marking-connection of the finished produc