Steel Transmission Parts Standard Deck Media Separation Vibratory Finishing Equipment

Basic Info.

| Model NO. | VBS(B)300 |

| Working Style | Shaking |

| Disc Diameter | Customer |

| Variable Speed | With Variable Speed |

| Sound Cover | Airtec |

| Speed Converter | Bosch Rexroth |

| Dosing Pump | Andose 9L/H |

| PU | 20mm |

| PU Material | Dow Chemicals |

| Control Box | Standing on Floor or Hang on Wall |

| Weight | 650kg |

| Separation Hole | 20mm, 25mm, or Customized |

| Power | 3.7/5 Kw |

| Size | 1370X1370X960mm |

| Machine Size | 300L, 10 Cubic Feet |

| Transport Package | Wooden Box |

| Specification | 300L |

| Trademark | Inovatec |

| Origin | Huzhou, China |

| HS Code | 84639000 |

| Production Capacity | 3000 |

Product Description

Steel Transmission Parts Standard Deck Media Separation Vibratory Finishing EquipmentCatalog Download

https://inovatecmachinery.en.made-in-china.com/Product-Catalogs/

Our vibratory finishing equipment VBS (B) are suitable for deburring and metal polishing of aluminum, brass, copper, stainless steel, and iron workpieces such as machined parts, injection molding parts, stamping parts, and die casting parts.

Vibratory Finishing Equipment Product Description:

In the mass finishing process, a container consisting of the workpieces and tumbling media is subjected to a controlled gyratory vibration. The vibration causes the tumbling media and workpieces to rub against each other, resulting in a polished look. Vibratory deburring is one of the most cost-effective mass finishing processes as it requires minimal or no labor.

Inovatec offers continuous feed and batch feed variants of tumbling equipment. The unload flap and separation screen allows quick separation of workpieces from the tumbling media. Our VBS (B) series machine has an extended separation deck with multiple separation holes.Applications includes: what is deburring, types of deburring process, steel deburring

Vibratory Finishing Equipment Feature:

- Digital process timer

- Low profile design

- Wide opening for big size parts

- Stress relieved and enhanced with blasting

- Default manual parts media separation

- Extended separation deck

- Wear resistant PU lining from Dow Chemicals

Vibratory Finishing Equipment Optional setting:

- Optional Items

- Sound Cover

- Compound Dosing Pump

- Pneumatic flap control

- Variable Frequency Drives

- Control box standing on the floor or hang on the wall

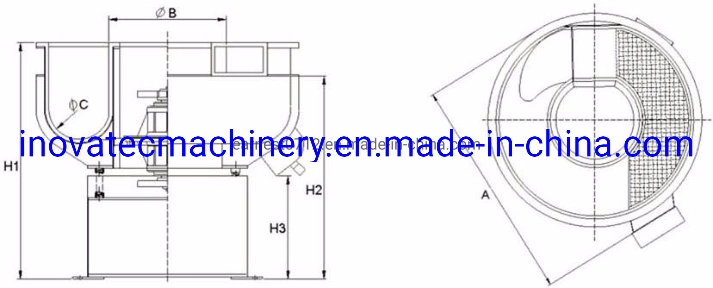

Vibratory Finishing Equipment Technical Drawing:

Vibratory Finishing Equipment Technical Data:

| Model | VBS(B)100 | VBS(B)150 | VBS(B)200 | VBS(B)300 | VBS(B)400 | VBS(B)600 |

| Total volume(L) | 100 | 150 | 200 | 270 | 480 | 660 |

| Max overall dimension(mm) A | 1080 | 1170 | 1200 | 1370 | 1430 | 1860 |

| Motor installation tube(mm) B | φ460 | φ460 | φ530 | φ630 | φ630 | φ900 |

| Process bowl width(mm) C | φ220 | φ260 | φ252 | φ275 | φ330 | φ390 |

| Unload width(mm) | 250 | 210 | 250 | 320 | 380 | 470 |

| Machine height(mm) H1 | 980 | 860 | 940 | 960 | 1270 | 1140 |

| Unload height(kw) H2 | 800 | 710 | 770 | 760 | 1090 | 925 |

| Media unload height(kg) H3 | 470 | 440 | 360 | 290 | 570 | 400 |

| Motor(kw) | 1.5/2.2 | 2.2 | 3 | 3.7/5.0 | 5 | 5.5/7.5 |

| Weight(kg) | 280 | 320 | 460 | 650 | 780 | 1180 |

Vibratory Finishing Equipment Product info:

Vibratory Finishing Equipment Company introduction:

Vibratory Finishing Equipment Optional settings:

Metal Surface Finishing Treatment Successful Project: Parts before and after vibratory polishing, vibratory deburring, cleaning, edge rounding, descaling, degreasing, de-oiling, cleaning, edge breaking,radiusing:

Mass Finishing Equipment and Tumbling Media Packing and shipment: Payment:

FAQ:

Q: How is Inovatec machinery brand?Inovatec Machinery is famous Top 3 brand mass finishing equipment and consumables manufacturer of China, has:- 25 years: vibratory finishing machines and tumbling media manufacturer experience.- 20000 square meters factory-2 year warrantyQ: What Certifications do you have?ISO9001, CE, certifications etc. 100% quality check, and testing before shipment

Q: What is Inovatec Machinery equipment warranty?2 year warranty for all Inovatec Machinery equipmentLifetime maintenance will be provided after the 2 year warranty period expires

Q: How you guarantee tumbling media quality?We make quality tracking from raw material until quality check before shipment. We keep record of quality test including wearing and cutting. For bulk and OEM order, we follow your testing methods and keep track of wearing and cutting. If the quality does not meet the standard, we will not make the shipment. Q: What is your Payment method?Accept payment via T/T (Bank transfer), Western Union, Money Gram, and PayPal;Accept L/C at sight (bulk order)

Q: What is your Minimum order amount?For machine minimum order is 1 PCS. For tumbling media minimum order is 1000kg or 2000 lbs as one pallet. You can ship less amount of media if ship with the machine. Sample order is allowed to ship less amount of tumbling mediaQ: What is your way of packaging?Fermentation wooden pallets for media, 1000kg per pallet, 25kg/plastic bag Customize packaging and logo printing is available for discussWooden box for equipment and compoundQ: How long is your production time?15 working days for sample order;20-25 working days for bulk order.Emergency order can be fulfilled in a week Q: What is the Shipping Way?20-30 days by sea to your nearest seaport2-5 days by air to your nearest airport3-5 days by express to your doorstepQ: What is the nearest Port:?Shanghai, Ningbo and Yiwu are the closest port.

Contact us: