Simple Type Coil Sheet Metal Slitting Line Cut to Length Line

Basic Info.

| Model NO. | ZH1250 |

| Control | PLC Delta |

| Cutting | Hydraulic / Electric |

| Motor | 30kw |

| Delivery Time | 40 Days |

| Warranty | 2 Years |

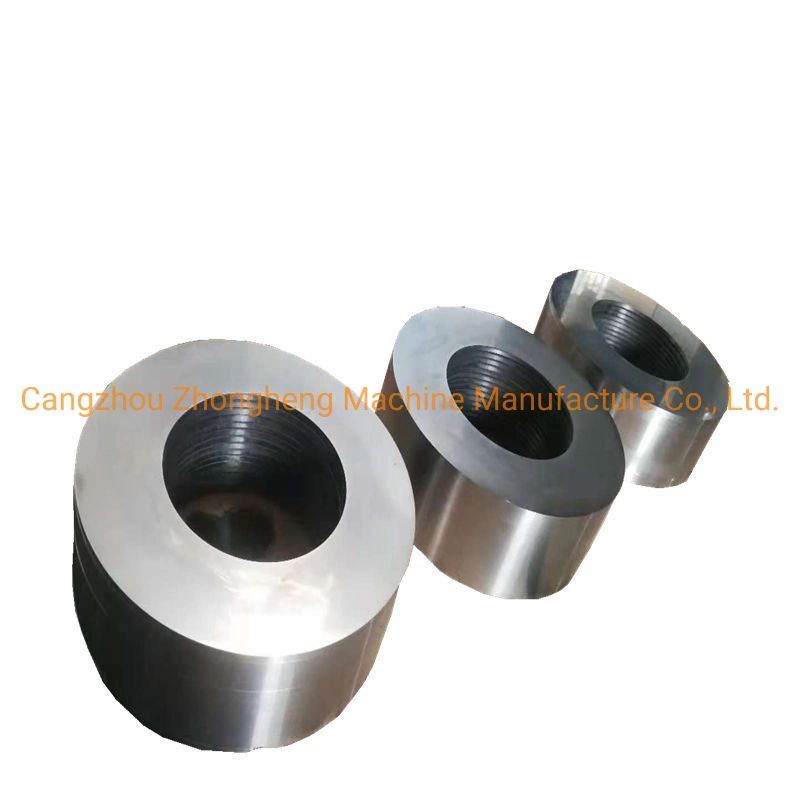

| Cutting Blade | Cr12 MOV |

| Key Selling Points | Easy to Operate |

| Width | 500-1500mm as Custom Profile |

| Speed | 60m/Min |

| Voltage | 380V |

| Suitable Material | PPGI Gi |

| Thickness | 0.3-3mm |

| Feature | Simple Type Coil Sheet Metal Slitting Line Cut to |

| Transport Package | Plastic File |

| Specification | 0.3-3mm |

| Trademark | ZH |

| Origin | Hebei, China |

| HS Code | 8455221000 |

| Production Capacity | 20 Sets Per Month |

Product Description

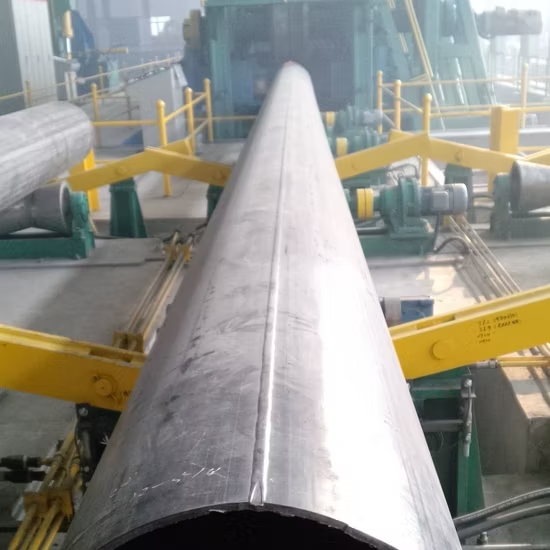

Application:It is suitable for the longitudinal shearing of the metal coils and rewinding coils.Advantages:Easy to operate, slitting quality is high, excellent material utilization, Stepless shearing speed regulation, etc.Structure:It consist of uncoiler, feeding and positioning, slitting unit, recoiler, etc.Applicable Materials:Tinplate, silicon steel, aluminum, copper, stainless steel and galvanized steel, etc.

Applications of Simple type coil sheet metal slitting line cut to length line

Coil Raw Material:

Stainless Steel Coil(ss) Galvanized Coil (GI) Galvalume Coil(GL)

Prepainted Galvanised Steel (PPGI) Prepainted Galvanlume Steel(PPGL)

Aluminium Coil and Copper coil Low Carbon Steel Coil Silicon Steel Coil

Simple type coil sheet metal slitting line cut to length line

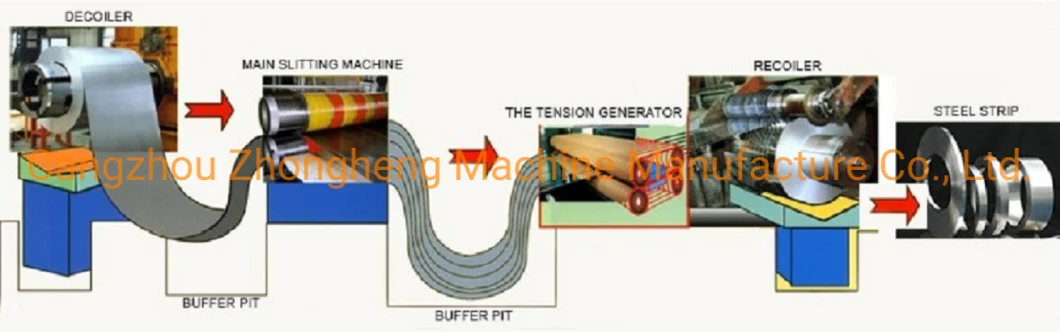

1.Machine composition

| 1 | Loading coil Car |

| 2 | Decoiler 5Ton -15Ton for Option |

| 3 | Straightener Device (Optional) |

| 4 | Head Shear /pinch roll/ |

| 5 | Bridge/loop pit |

| 6 | Side guide |

| 7 | Mail Slitter |

| 8 | Side Guide& scrap winder |

| 9 | Bridge/Loop pit |

| 10 | Separator&Tension station |

| 11 | Recoiler and support Arm |

| 12 | Unloading coil car |

| 13 | Hydraulic system |

| 14 | Electronic controller(PLC , Control table) |

2.Parameter:

a.Raw Material data:

Material thickness:0.2-3.0mm

Material width:400-1500mm

Coil I.D.: Φ508mm/Φ610mm

Coil O.D.: ≤Φ1600mm

Coil weight:15 tons max

b.Finished Product:

Coil I.D.: Φ508mm

Coil O.D.: ≤Φ1600mm

Coil weight:15 tons max

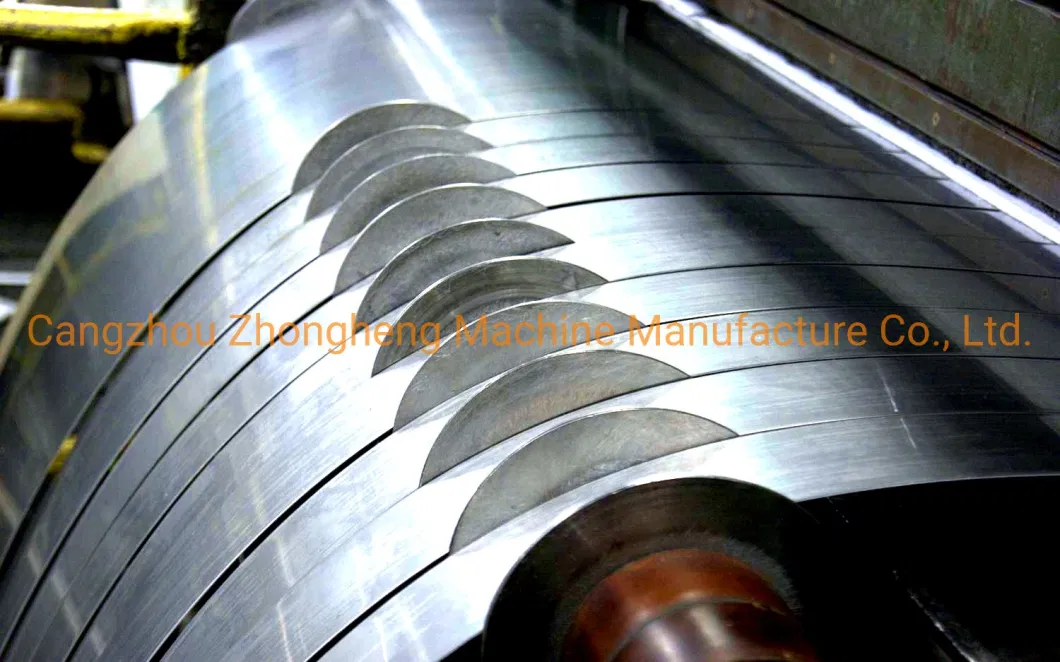

Narrowest strip width slit into: 20 mm

Width cutting precision: ±0.05mm(strip thickness≤1), ±0.1mm(strip thickness>1.5mm)

Slitting Bur: 0.05 minimum, 5% of the trip thickness

Rocker: plus or minus 1 mm/m or less

Recoiling Looseness(mm) : ≤2 mm

Pcs of Slitting(Max) : 25 PCS

Line working speed: 60m/min max

Total power: Approx.120kw

3.Detail of description of slitting line:

A steel factory need to buy several lines for different requirements or big capacity. the narrow coils/rolls are widely used in Steel Pipe Factory, Steel Structure Factory, Storage System Manufacturing Factory, combined with Roll Forming Machine, Power Punch Machine, Pipe Mills.

1.Function: It is used to the longitudinal cutting for the steel coils and rewinding the slit strips into coils.

2.Advantages: Convenient to operate, high cutting precision and utilization factor of the material, adopts the infinitive speed.

3.Structure: Compose of Decoiler, feeding device, slitting machine, recoiler (Rewinding) machine.

4.Material can be processed: galvanized steel, stainless steel tinplate, silicon steel ,copper and aluminum, etc.

5.lndustries can be applied to: steel factory, transformer, electrical motor, electrical equipment, car, building materials, door, packaging industries.

Packing and Shipping1. Simple type coil sheet metal slitting line cut to length line need one 20/40 feet container to load .2.We have professional technicians for loading to make sure machine has no damage.3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Company Introduction

FAQ

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warranty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .

More information please send inquiry to us , you will get reply within 12 hours !