Longitudinal Seam Cold Formed Tube Mill Line of Low Carbon Steel

Basic Info.

| Model NO. | ERW 76 |

| Type | Pipe Production Line |

| Transport Package | Nude Packing |

| Specification | Customized according to customer request |

| Trademark | Brilliance Machinery |

| Origin | China |

| HS Code | 8455102000 |

| Production Capacity | 70 Sets |

Product Description

Product Description

Product Name: tube mill for carbon steel pipe production line

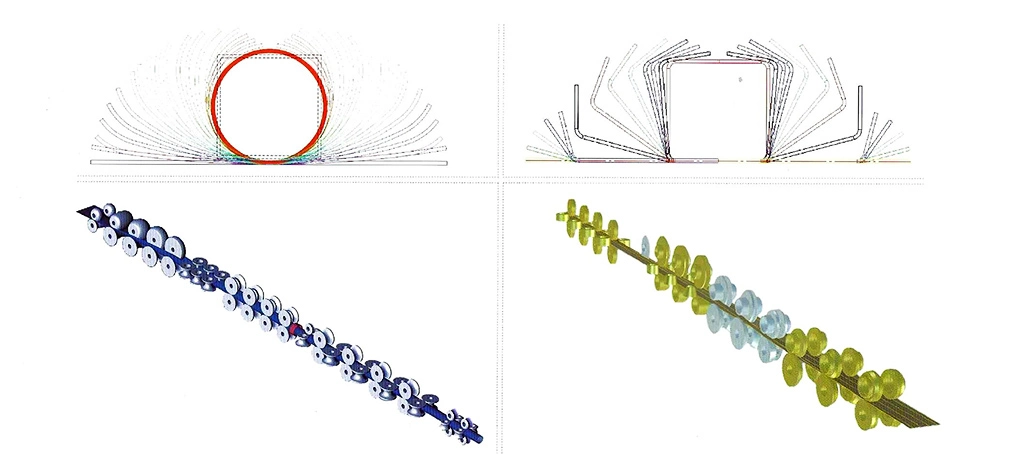

The high frequency straight seam welded pipe mill is used to level the fixed strip after slitting line, and entry it to forming machine, bend to open pipe by rollers, melt the strip edges through the high frequency current,squeeze and weld the pipe to be closed by the squeeze roll. The high frequency pipe mill also called ERW pipe mill.

High frequency welded pipe mill is the special equipment producing welded steel pipe and profile pipe for industries such as metallurgy, construction, transportation, machinery and so on. Taking cold or hot rolled steel as raw materials, through cold formed and high-frequency welding to produce the round pipe, square pipe and rectangle pipe.

Technical processing of ERW pipe mill :

Loading coil --- un-coiler --- leveling --- shear and butt welder --- horizontal accumulator --- forming --- HF welding machine --- external burr removing --- cooling --- sizing machine--- cutting by flying saw --- run out table --- packing

Detailed Photos

Product Parameters

Main technical specifications of straight seam welded pipe mill

| Model | Round Pipe | Square & Rectangular Pipe | Speed(m/min) | Floor area(m2) | ||

| Diameter(mm) | Thickness(mm) | Size (mm) | Thickness (mm) | |||

| ERW 32 | 10-38 mm | 0.5-2.0 mm | 10x10~30x30mm | 0.5-1.6mm | Max.120m | 12x40 |

| ERW 50 | 15-51 mm | 0.5-2.5 mm | 15x15~40x40mm | 0.5-2.0mm | Max.120m | 12x60 |

| ERW 60 | 16-60 mm | 0.5-3.0 mm | 15x15~50x50mm | 0.5-2.5mm | Max.120m | 12x60 |

| ERW 76 | 20-76 mm | 1.0-4.0 mm | 20x20~60x60mm | 1.0-3.0mm | Max.120m | 16x80 |

| ERW 89 | 25-89 mm | 1.0-4.5 mm | 20x20~70x70mm | 1.0-3.5mm | Max.120m | 16x100 |

| ERW 114 | 38-114 mm | 1.0-5.0 mm | 40x40~90x90mm | 1.0-4.0mm | Max.80m | 16x100 |

| ERW 165 | 60-165 mm | 2.0-6.0 mm | 50x50~150x150mm | 2.0-5.0mm | Max.60m | 16x100 |

| ERW 219 | 89-219 mm | 3.0-8.0 mm | 80x80~200x200mm | 3.0-8.0mm | Max.50m | 16x150 |

| ERW 273 | 114-273 mm | 4.0-10.0 mm | 100x100~250x250mm | 4.0-10.0mm | Max.40m | 18x160 |

| ERW 325 | 165-325 mm | 4.0- 12.7 mm | 100x100~300x300mm | 4.0-12.0mm | Max.30m | 24x180 |

| ERW 426 | 19-426 mm | 5.0-14.0 mm | 150x150~350x350mm | 5.0-14.0mm | Max.30m | 24x180 |

| ERW 508 | 219-508 mm | 6.0-16.0 mm | 200x200~400x400mm | 6.0-16.0mm | Max.25m | 24x180 |

Note: The data in the form is just as reference according to general ranges.Normally we design and produce the straight seam welded tube mill according to customer's specific requirement. So every customer can buy his own ERW straight seam welded pipe mill from us.

Packaging & Shipping

FAQ

1. Q:Are you manufacturer?

A: Yes, we are manufacturer and trading company. We have our own technical team, and about 45000 sq.m workshop. Welcome to visit us .

2. Q:What kind of information you need before you give quotation?

A: The pipe diameter and thickness range which you gonna make or the profile drawings, material information, and your other special requirements.

3

Q:What kind of payment terms you can do ?

A: We are flexible about payment terms,such as T/T, L/C. we can help you on financing also,please contact us for details.

4. Q: Can your factory customize the machine for clients ?

A: Yes, we can.

5. Q:How do you do QA?

A : We have team do strict QA.

- Every gearbox will be tested for 8 hours with oil inside to guarantee there is no leak.

- Every shaft will be inspected for the centering jumpiness.

- Every roller will be checked to make sure its tolerance, critical parts will be inspected for all dimensions.

- For HF welder, we will do factory commissioning and will test all the protection functions.

- For Flying computer saw, the factory inspection will also be proceeded before shipment.

6. Q: What is the warranty time for your ERW pipe machine? A: warranty period of ERW pipe mill : 12 months after commissioning.

7. Q: How about after-sales service ?

A: We will send professional engineers to final customer's factory for machine installation , commissioning and carefully working training . The final customer will afford related cost.

8. Q:Why should i choose you? What's the difference between you and other Chinese supplier? A: We are concentrating on this pipe mill field for more than 15 years.We have professional researching, designing, processing, testing and after-sales service teams. Our pipe making machine lines have been exported to many countries , such as Turkey, Russia, Egypt, Vietnam etc.9. Q:What should i do if i just start a new business ? A: contact us immediately, we can provide pre-sales consultant service free of charge.