High Quality Carbon Steel High Frequency Seam Welded Stainless Steel Pipe Tube Mill Machine

Basic Info.

| Application | Industry |

| Type | Pipe Production Line |

| Transport Package | Sea Delivery |

| Production Capacity | 1500 Sets/Year |

Product Description

Product Description

High frequency straight seam welded pipe production line is mainly used to produce electric welded steel pipes with φ60~φ219mm and wall thickness of 2.0~6.0mm, and can also produce square and rectangular pipes and special-shaped pipes not exceeding the range of round pipes. API 5L tubes can be produced later by adding necessary equipment. The production line is designed and manufactured on the basis of digesting and absorbing similar equipment at home and abroad, combining with my country's national conditions, boldly innovating, and listening to users' opinions extensively. The equipment is economical, reliable and stable.Technical Parameter

| Parameters | Round pipe | Square pipe | Rectangle pipe |

| Tube size | 88-219 mm | 90x90 - 170x170 mm | 40×60-200×100mm |

| Thickness | 2.0-6.0mm | ≤5.0mm | ≤5.0mm |

| Material | Hot and cold rolled, Galvanized steel, Black steel Low carbon steel, low alloy steel Steel | ||

| Speed | 10M/min~45M/min | ||

| Length | 6-12m | ||

| Max. Coil weight | 15 tons | ||

| Low carbon steel and low alloy steel | σB≤520mpa σS≤345mpa | |

| Steel Coil | inner diameter | φ650-φ710mm (to be determined) |

| Outer diameter | φ1100-φ2000mm | |

| Roll weight | ≤15 tons | |

| Strip width | 190-690mm | |

| Electrical installed capacity | about 1200KVA | |

| Compressed air capacity | 2m3/min 4-7Kg/cm2 | |

| Coolant capacity | 50 tons/hour | |

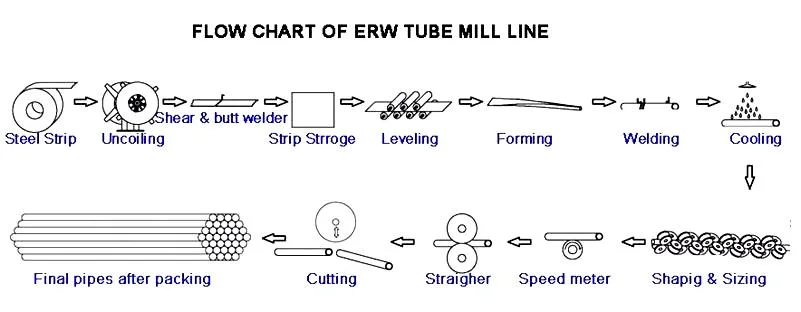

Uncoiling → straight head, pinch leveling → shearing butt welding → looper → forming, high frequency welding, deburring, on-line zinc replenishment, cooling, sizing, rough straightening → flying saw sizing → inspection and collection → packing →Weighing→Marking→Storage

| Usage | It is used to accept the strip coil, transport it to the decoiler, and lift the strip coil to the center of the coil head | ||

| Structure | It is composed of material rack, traveling mechanism, oil cylinder, guide rail, etc. | ||

| Capacity | ≤15T | Hold up | Hydraulic |

| Moving Mode | Motor with cycloid reducer drive | ||

1. Uncoil

| Usage | For hanging and supporting strip coils to provide raw material for production lines | |||

| Capacity | ≤15T | Braking method | Pneumatic brake, solenoid valve control | |

| Uncoiler | Hydraulic expansion and contraction | Single cone hydraulic expansion and contraction | ||

| Usage | Used in conjunction with the uncoiler, the steel strip head is drawn from the uncoiler and sent to the pinch leveling machine for leveling | ||

| Structure | Press roller device, shovel head device, straight head device | ||

| Width | 190-690mm | Diameter | φ1100-φ2000mm |

| Usage | Leveling the steel strip from the uncoiler and straightening machine at the head and tail and delivering the steel strip to the shearing butt welding machine | ||

| Structure | Composition of pinch roller, leveling roller and transmission device | ||

| Width | 190-690mm | Diameter | φ1100-φ2000mm |

4.Shear & butt-welding machine

| Usage | It is used for shearing and butt welding of irregular parts of the head and tail of the strip to ensure the continuous production of the welded pipe unit | |||

| Cutting Steel Coil | Width | 190-690mm | Thickness | 2.0-6.0mm |

| Classification | Shear Butt Welding Machine | Hydraulic shearing, mechanical tightening, manual welding | ||

5.Horizontal Accumulator

| Usage | It is used to store strip steel, continuously feed the pipe welding machine, and ensure the continuous production of the pipe welding machine. | ||||||

| Width | 190-690mm | Thickness | 2.0-6.0mm | ||||

| Classification | Horizontal looper | By clip feeding device, looper body assembly, discharging device and electrical control device | |||||

| Motor | 5.5KWx15 | Feeding Speed | Vmax=120 m/min | ||||

| Diameter | 7.0m | Capacity | 28T | ||||

Company Profile

Raintech Machinery is specialized in roll forming , coils processing , tube mill engineering manufacture since 2008.Our leader engineer Mr. Xu , as one of our company founder, was the team leader worked in china industry center since 1990s', which team was the first group of roll forming technology in china , was the lable of china most advance technology level.After 16 years development, we have devoted to the practise and improving the dmost advance design , most economic but stronger structure and save human work cost by maximum limit.Our machines widely used in steel structure , bridges highway , automobile, solar energy, wind power machines, traffic railway construction , three -dimensional parking system, central air conditioner system, sea water desalination, Petroleum and petrochemical, construction machinery, project machinery and port machinery , Modern granary, shipbuilding etc.

Our successful and reputated projects :

Roll forming machines : highway guardrail, automobile bumpers, Truck beam, construction metal sectionpurlins, roof, wall,decking floor, solar structure , cable tray, storage racks etc.Metal coils processing lines and tube mill line ,Cut-to-Length lines, Slitting lines, Tension Leveling lines and Precision Leveling machines,SS tube mill :38mm, 50mm, 76mm etc. ERW tube line: 32mm,50mm, 63mm,76mm ,114mm, 127mm,140mm,165mm, 189mm 219mm ,257mm ,409mm.We know well that our high reputation among the clients and users based on stable quality and sincerely after-sales service. We will keep devote to provide the great support for the clients from all over the world.Welcome all the partners and users from all over the world cooperate with us!

1. Q: Are you a Manufacturer or a trading company? A:We are a professional manufacturer with more than 15 experience in manufacturing, assembling and selling in this field. We have our own factories as well as trading companies2. Q: How long have your factory been in this field? And how many staff do you have? A: We have been in this field mode than 12 years since the year of 2008, total staff more than 100.3. Q:Where are you and how can I visit you? A: Our factory located in Jinan City, Shandong Province China, contact us before your visit in order that we can arrange the good reception.4. Q: Can you provide a customized solutions? A: Yes, our engineers are pleased to listen your idea and customized design is available5. Q: What about the warranty? A: We provide 12 months warranty since the machine arrival. free charge of spare parts and regularly maintenance service.6. Q:How about the delivery time ? A: The delivery time is different on different products.We never receive any complain from our customers for the delivery time7. Q: What about the package and shipment , worry about damage in shipping . A:The machine will be packaged by multilayer plastic wrap for anti-humidity on the sea. The strong steel wire roops will be used for fix the machines in container to avoid any damage in transportation.8. Q: What kind of payment does your company support? A: T/T, 100% L/C at sight, Cash, Western Union are generally accepted.9. Q:Do u support on installation and training? A: Yes, we provide engineers to your site for installation and training, if conditions not allowed, we provide team work by video conference for installation gaudiness on line.

1. OEM Design&Production Our active engineer and design team can make the special machine according to customer's special requirements.2. Delivery in Time Assurance We assure the machines your ordered will delivered at promised time3. Free Installation&Training We provide the installation and training by online video support; local installation and training service team; send engineer for installation and training; installation operation video provided4. Your Payment Protection You can pay through Alibaba to protect your advance payment5. Online Factory Inspection Service The factory inspection before your order, will be provided online by video meeting app, like room, wechat,skype etc..6. Long Life Maintenance of Machine We keep provide the maintenance for all machine life7. International Third Party Inspection Supported You can appoint the international third party party, such as TUV, SGS,BV, do inspection before shipment