High Frequency Galvanized ERW API Round Square Rectangluar Stainless Steel Seamless Welded Pipe Making Machine Metal Profile Tube Mill Roll Forming Line

Package Size 220.00cm * 120.00cm * 120.00cm Package Gross Weight 750.000kg Nothing has been left to chance. Our automati

Basic Info.

| Model NO. | Customized |

| Condition | New |

| Customized | Customized |

| Theory | Inverter |

| Application | Industry, Decoration |

| Type | Pipe Mill |

| Weight | 288000 |

| Power | 150kw |

| High Frequency Powe | Customized |

| Mill Range | 10-219mm |

| Wall Thickness of Welded Tube | 0.5-5mm |

| Production Capacity Range | 100000mm |

| Annual Output | 6100t |

| Voltage | 220V/380V/415V/440V |

| Core Components | PLC, Bearing, Gearbox, Motor, Pump |

| Applications | Welded Tube |

| Mill Speed | 30-80m/Min |

| Key Sell Point | Long Service Life |

| Video Outgoing Inspection | Provided |

| Usage | Energy Supply Pipe |

| Machinery Test Report | Provided |

| Transport Package | Standard |

| Specification | Customized |

| Trademark | WONSTEN |

| Origin | China |

| HS Code | 8462991000 |

| Production Capacity | 500 PCS Per Year |

Packaging & Delivery

Package Size 220.00cm * 120.00cm * 120.00cm Package Gross Weight 750.000kgProduct Description

| High Frequency Galvanized ERW API Round Square Rectangluar Stainless Steel Seamless Welded Pipe Making Machine Metal Profile Tube Mill Roll Forming Line |

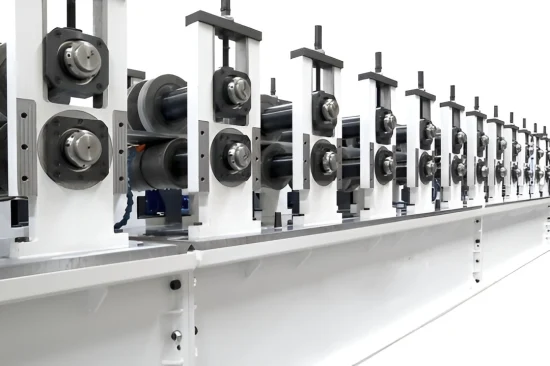

Nothing has been left to chance. Our automatic profiling tube mill lines are future-proof where new roller sets or modules can always be added later. The RF series roll forming lines are fast, accurate, and flexible, allowing sheet thicknesses from 0.3mm to 12mm at sheet widths up to 1400mm.

The Wonsten sheet metal roll forming machines contain highly innovative solutions. They have proven themselves in a wide range of sectors in construction, logistics, automotive, agriculture, road safety, consumer goods, and much more.

COIL UNWINDING MACHINEIt all starts with an unwinding machine. The VLB program ranges from simple and light to the most robust (20 tons) versions. They have variable-speed laser sensors and powerful integrated coil loading and unloading system.PUNCHING MACHINEDepending on the specifications of the finished product, a punching machine can be integrated into the roll forming line, either as a compact part of the line or as a standalone station. Although, they are always equipped with servo-controlled drives and touchscreen programming for high accuracy and speed. The tools can be single or multiple, with independent pneumatic drives and CNC programming.

ROLL FORMING STATIONSThe roll forming lines can contain different systems depending on the application and versatility desired by the customer. These can be quick-change cassettes, adjustable tools for producing profiles of different sizes, multiple tools for producing different profiles in the same arrangement, double roller sets with shared motorization, etc.

CUTTING AND UNLOADING PROFILES

The cut can be performed by a stationary saw, which makes the cut during a short stop, or by a high-speed, servo-controlled cutting station. The last-mentioned system allows the production of profiles without stops. In that case, our automatic unloading system must be used. It is of course possible to make straight cuts without waste but also cuts at an angle.

The unloading systems are developed customer-specific, such as unloading on both sides in combination with a stacking or pallet table.

CONTROL

Components are integrated into the automatic VLB roll forming lines. They are individually controlled by a powerful and intuitive CNC controller. This guarantees the connection between all process steps from the plate spool to the automatic unloading table.

PLATE WELDING UNIT

For companies with a high production speed, this welding system ensures that the ends of the plate on the coil are automatically welded (end of the coil with a new beginning), which saves a lot of time when replacing the coil, and the material waste is considerably reduced.

VERTICAL PLATE STORAGE SYSTEM

The vertical plate storage system is used when it is not possible to make a pit on the floor, which contributes to the continuous operation of the roll forming line.

Send to us