3100*20mm Spiral Pipe Mill

Introduction: HUAYE is a high and new technology enterprise specialized in design, development and manufacture of variou

Basic Info.

| Type | Pipe Welding Machine |

| Coil I.D. | 610-750mm |

| Coil O.D. | 1200-1800mm |

| Butt Welding Type | Single Wire Sub-Merged Arc Automatic Welding |

| Forming Type | Three-Roller Bending and Outer Control |

| Mill Type | Left Spiral |

| Thickness | 6-14 mm |

| Max. Coil Weight | 22 Ton |

| O.D. | 426-1420 mm |

| Material | Q235 |

| Coil Width | 500-1560mm |

| Transport Package | in Nude |

| Trademark | HUAYE |

| Origin | China |

| Production Capacity | 15-30/Year |

Product Description

Introduction:HUAYE is a high and new technology enterprise specialized in design, development and manufacture of various pipe mill.Including spiral welded pipe mill, ERW pipe mill, end facing and beveling machine, hydrostatic tester, pipe finishing section equipment, high precision slitting &cut to length line, pipe expanding machine, pipe straightening machine and some other pipe machines. Our pipe mill has been proven high efficiency, low maintenance and energy-saving during 30 years of practice. And we can supply one package service, from design, manufacture, installation, commissioning, guiding etc.).

Tube making machine is main product of HUAYE that are developed through years of research to combine the advanced knowledge and technology of the market. The production and inspection process from strip coils to finished tubes must go through dozens of processes in the main area and the finishing area of the welded pipe.

The production flow of tube making machine includes two parts: Mill section and finishing section

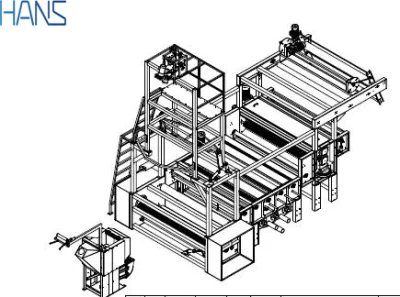

1. Mill SectionCoil Preparation → Uncoiler→ Pinch and leveler(2-roll pinching;5-roll leveling) → Strip position control→ shearing and end welding →Strip position control → Rotary shear →Strip position control→ Edge miller → Surface cleaning → Surface polishing→ Delivery machine → Pre-bend → Guiding Beam →Strip position control → Forming machine → Inner welding →Outer welding → Flying plasma cut →Deslagging →Pipe conveyor2. Finishing Section(X-ray inspection) →repair welding → end facing and beveling→ transition rack →hydrostatic test →(ultrasonic inspection) → repair welding → pipe storage

Machine parts in the working line

1) Uncoiled

2) Pinching & leveling machine

3) Manual/Electrical roll

4) End - Cutting & butt-welding machine

5) Rotary shear

6) Delivery machine

7) Guide board

8) Forming unit

9) Front bridge

10) Inside/outside welding device

11) Rear bridge

12) Flying saw cutter

13) Buried parts

14) Hydraulic system

15) Electric system

16) Inside/outside welder

17) Butt-weld car

18) Plasma cutter

19) Weld flux processing device

20) Beveling & end-facing machine

21) Hydraulic tester

22) Finishing equipment

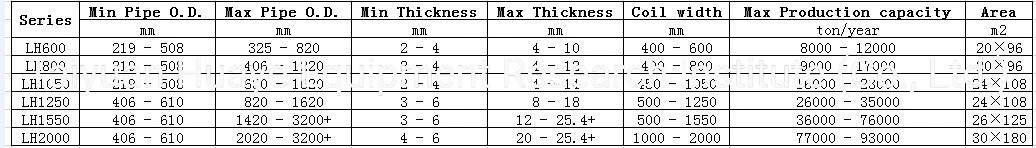

Model

Tube Mill :next

Send to us